Ford’s proprietary spark plug design actually worked well. Only when removal came around did its unique properties show their fatal flaws.

If there’s a ranking for nightmare experiences changing a car’s spark plugs, trucks, and SUVs with Ford’s early Triton 3-Valve V8 engines from the early 2000s is up there.

Whereas most spark plugs use a one-piece design consisting of a terminal, insulator, shell, and head mostly made of threads surrounding a center electrode, Ford’s 5.4L Triton 3-Valve V8 spark plug has an extended two-inch electrode surrounded by ceramic and extra shielding.

It’s a proprietary design never used in any other engine before, its unique properties that made removal after the recommended 100,000 miles almost impossible.

Owners who tried to change these unique spark plugs almost always break them upon removal, leaving the bottom half stuck in the spark plug hole. It was a nightmare for early owners. Today, there’s an approved TSB from Ford and special tools to make removing broken spark plug pieces tolerable.

But, why did Ford decide to break the mold and use a unique spark plug design in the first place?

Let me tell you why.

Looking to upgrade its 2-Valve Triton 5.4L V8 engine, the workhorse power unit for F-series, E-Series, and SUV lineup, Ford chose to engineer a 3-Valve version.

With a redesigned cylinder head, one extra cylinder valve, and Variable Cam Timing, these improved Tritons made 300 HP and 365 lb-ft, +40 HP and +15 lb-ft over its predecessor. More importantly, it made more power down low, where most Fords with this new engine will operate.

Other notable improvements on this new 3-valve engine were an induction system that boosts torque at low engine speeds, a more-rigid cast-iron block, and an innovative spark plug that “allowed Ford to boost Triton’s power without making the engine larger.”

“The plug’s 10-millimeter diameter is smaller than a regular spark plug. And the electrode extends about 2 inches past the threaded area. That allows bigger engine valves, which in turn increases power.” -MotorWeek

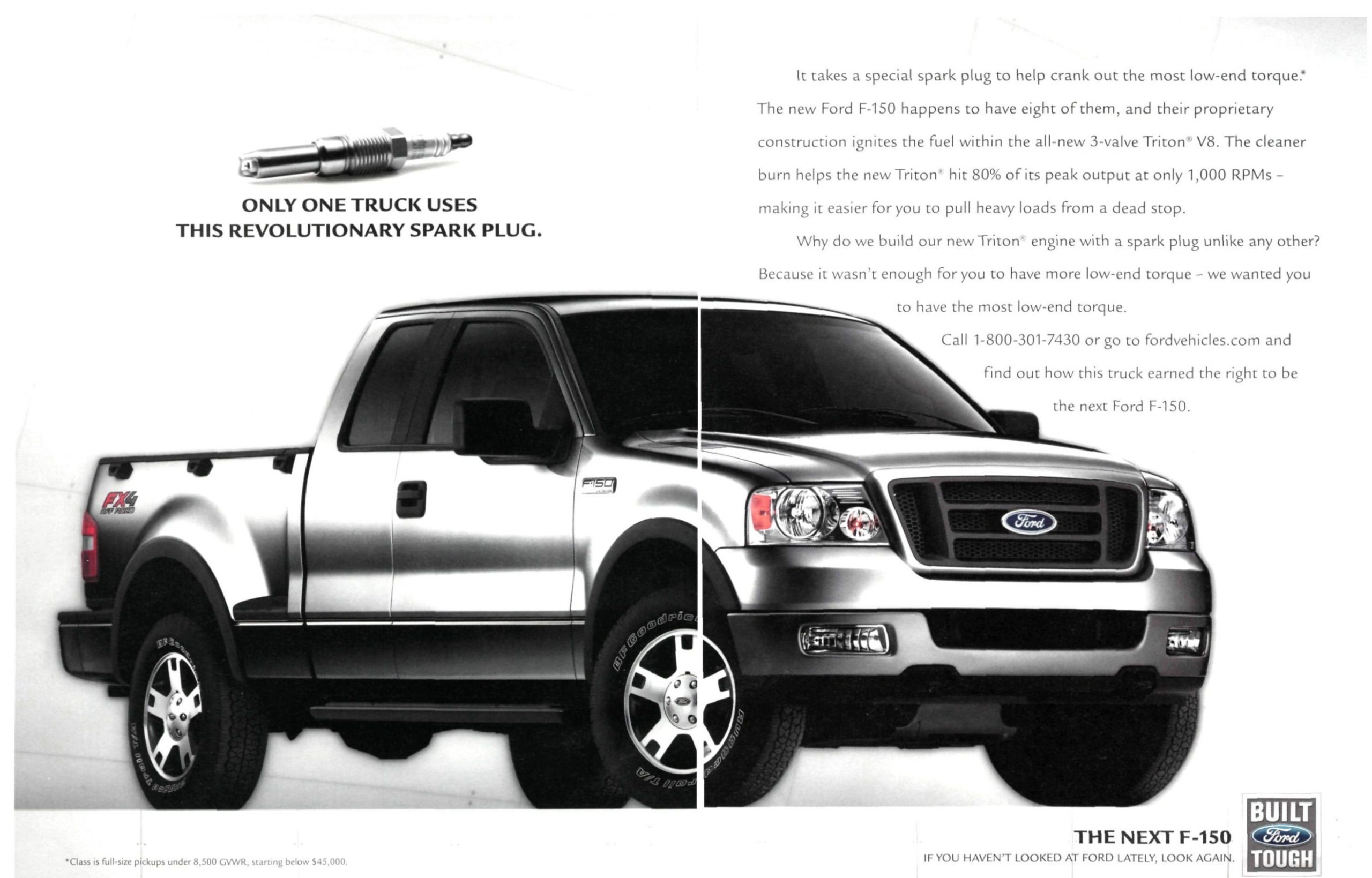

Ford was so proud of this unique spark plug that their ads of the new F-series at the time focused solely on that.

Here’s the ad I came across in Sports Illustrated.

“It takes a special spark plug to help crank out the most low end torque” the ad reads.

“The new Ford F-150 happens to have eight of them, and their proprietary construction ignites the fuel with the all-new 3-Valve Triton V8. The cleaner burn helps the new Triton hit 80 percent of its peak output at only 1,000 RPMs making it easier for you to pull heavy loads from a dead stop.”

And here’s a shot of the Triton 5.4L V8’s 3-Valve combustion chamber with centralized spark plug.

If Ford used a conventional looking spark plug, they would have to enlarge that centralized spark plug hole, making the intake and exhaust valves marginally smaller. Consequently, smaller valves mean less overall air when open. It’s hard to justify a new engine when power gains are so small.

Spark plug design flaw

Whoever designed the original Motorcraft PZT 1F Platinum spark plugs decided a crimped lower electrode shell on the bottom half was sufficient for the life of the spark plug.

What Ford did not anticipate was carbon and rust buildup.

Carbon, a by product of combustion, would build up between the cylinder head and the extended electrode shell.

And, since the spark plug extension is steel against an aluminum head, there’s corrosion and rust buildup, too.

Simply put, the binding torque of the carbon buildup and rust slowly becomes greater than the 2-piece plug’s crimp joint strength.

The longer those original Motorcraft plugs are in there, the greater chance of breaking when you pull them out. It didn’t help Ford specified 100,000 mile change intervals.

The TSB that Ford eventually published offered a temporary workaround that involved ever-so-slightly cracking open a spark plug, filling spark plug holes with carb cleaner, and letting it sit overnight. The carb cleaner would break up the carbon, increasing the chances of a break-free removal.

Motorcraft and Ford have since redesigned those original spark plugs. The new replacement ones are still a 2 piece design but instead of being pressed (crimp,) they are laser welded. Supposedly, this means they are 3x stronger.

Ford also redesigned 3V Triton V8 heads in 2008 to accept a totally redesigned, one-piece spark plug. Instead of that smooth shielding covering the bottom half, it’s mostly threads.

Check out a side-by-side screenshot of the OG problematic plugs and the refreshed version 2.0 plugs. The new heads and plugs are not cross-compatible meaning you can’t slap on the new heads on an older 3V Triton V8, and, the same goes for the plugs.

Despite the improved two-piece replacement spark plugs with welded bottom halves and the updated one-piece plugs, there are a lot of Fords with 3V Triton V8s with original spark plugs floating around.

When those Fords get misfiring issues and owners can no longer put off that plug replacement, they are in for either a weekend long ordeal or an expensive bill from their Ford dealership.

In conclusion, the original Motorcraft spark plugs weren’t all bad, they performed as designed, often, for far longer than they were engineered for.

An unfortunate design flaw engineers should’ve caught and rectified in testing was that carbon buildup and rust problem.