“Creating this custom engine is the epitome of being an engineer and gear head.”

Virginia-based Honda drag racing parts specialist Prayoonto Racing announced earlier yesterday (Jan 5,2021) they are collaborating with mechanical engineer Craig Williams of Neutron Engines to produce the world’s first Honda V8 engine made by pairing two K24 (K-series) engines.

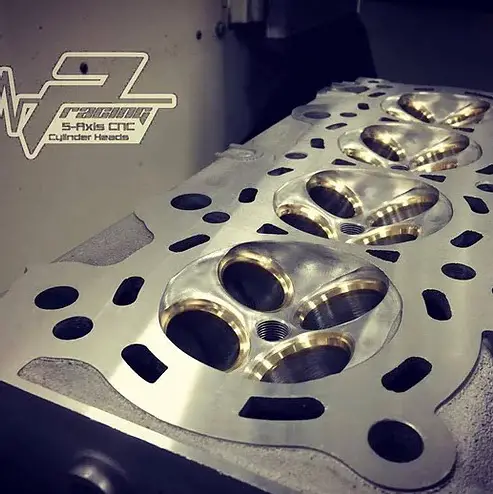

Williams is doing all the hard work including computer aided design, prototyping, and actually building the engine while Prayoonto Racing will provide Williams with its high-flowing “K-series winner circle” drag racing heads and K-Cams, drag racing parts on naturally aspirated racing builds that have seen naturally aspirated Hondas hit mid-7 seconds in the quarter mile.

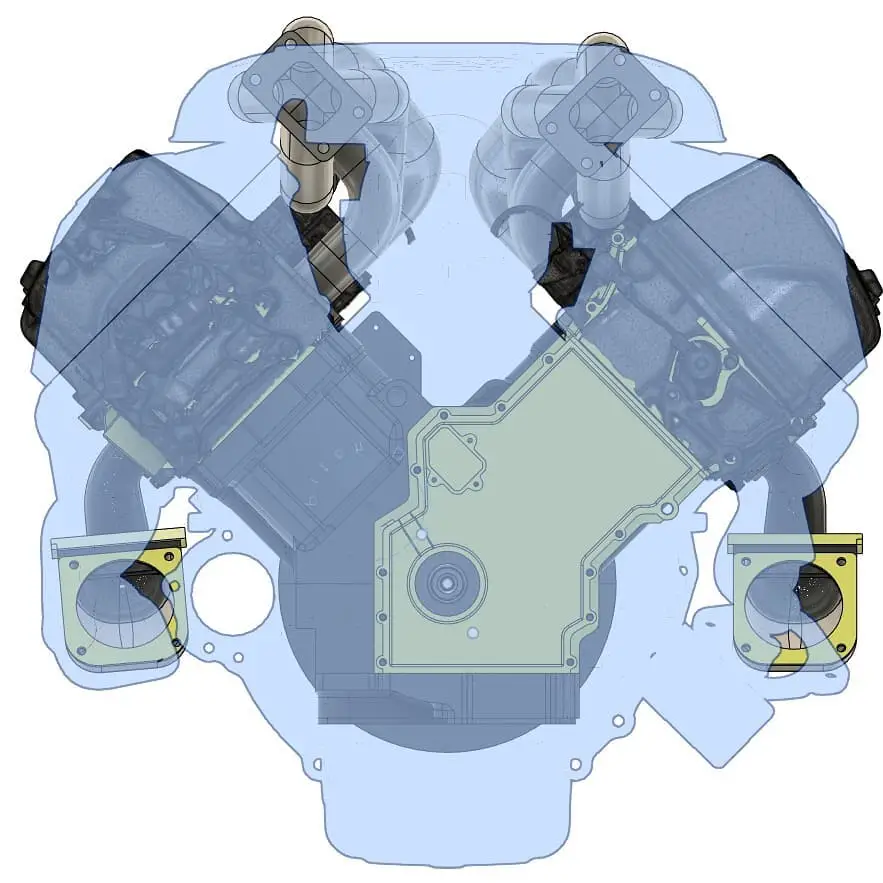

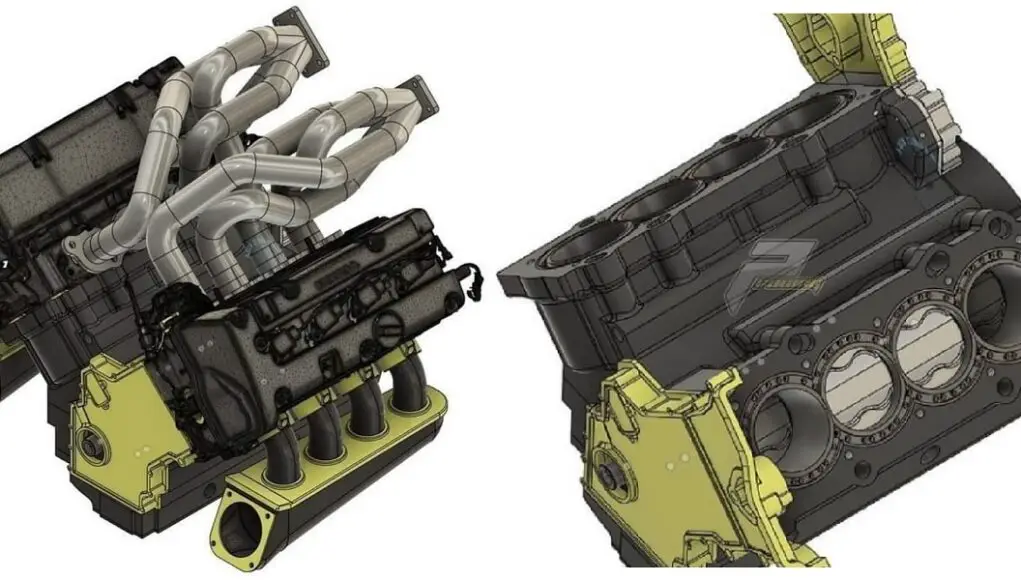

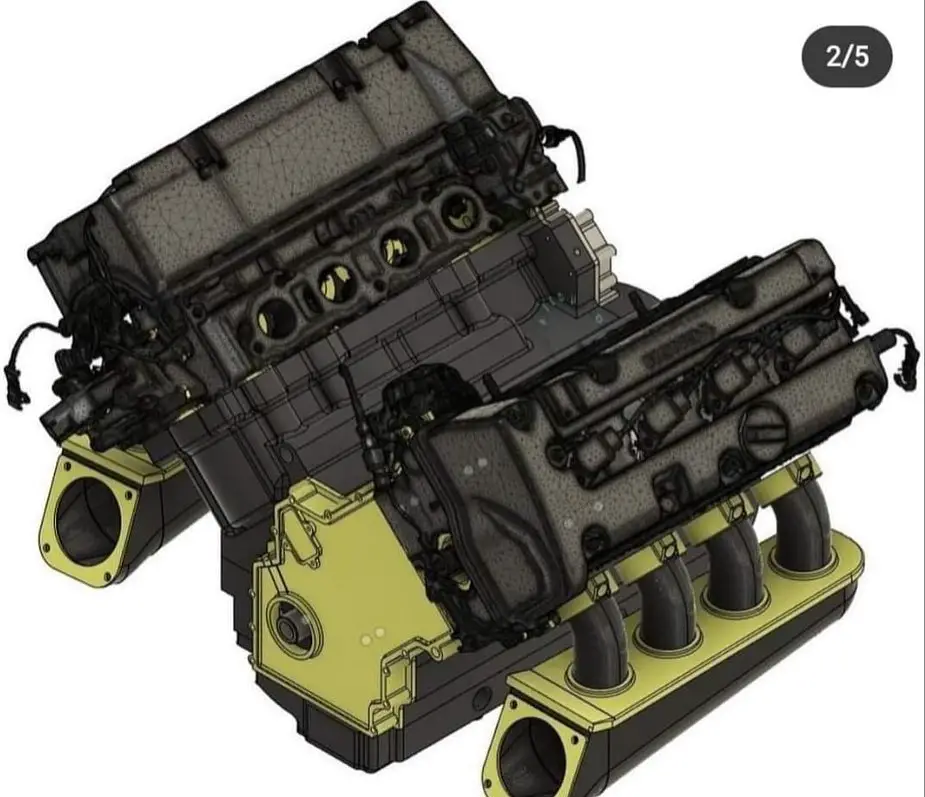

Check out his initial design photos and CAD work below.

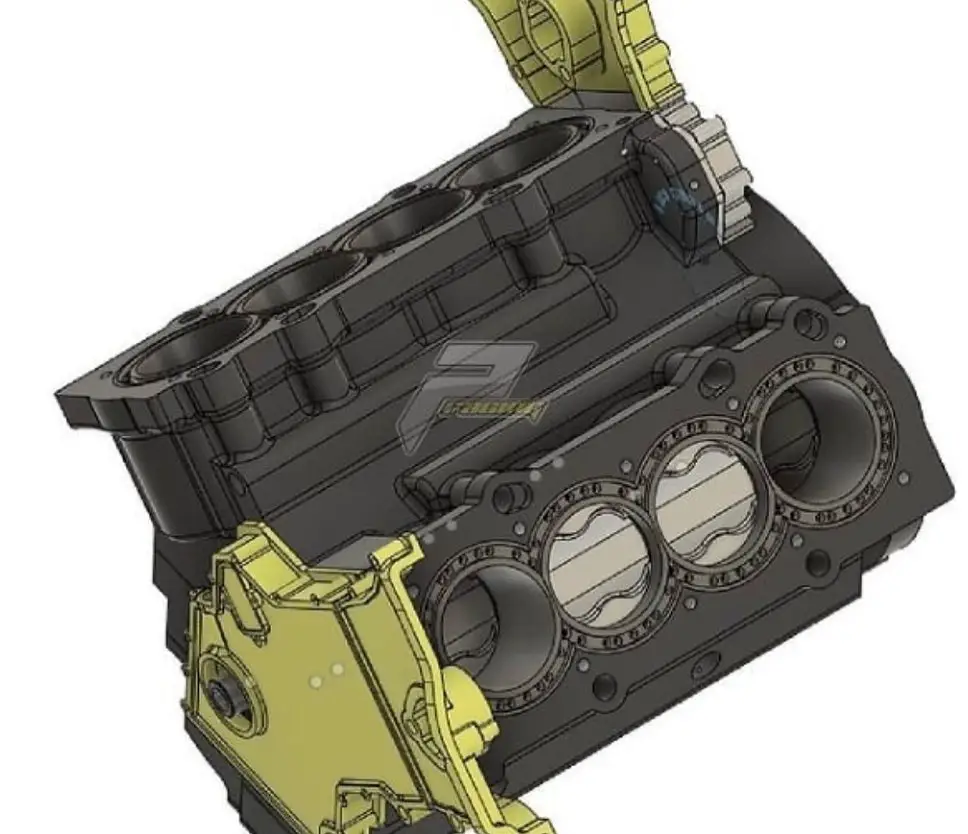

If you’re skeptical about this project being some sort of vaporware, I assure you, Williams is “putting the pedal to the metal” and already has billet blocks, 5-axis CNC’d crankshafts and heads being made. Below are photos of rough billet blocks and heads headed to the United States courtesy of PPR Motorsports. From what I’ve read online, PPR is the “go-to” for this kind of race-spec engine work, most likely work sublet out by Prayoonto Racing.

According to his LinkedIn, Williams is currently a Hardware mechanical engineer for Axon, a Scottsdale-based public safety technologies company known for their body cameras used mostly in law enforcement and local police forces.

As for this project,

“It all started 5 years ago when I drug home a Honda K24 from the pick and pull and informed my fie it would be taking residence in the bedroom next to my desk.” Williams said

“I scanned the entire thing. I started to mock-up my design in CAD. I am still finding dots all over the house and garage years later.”

When Prayoonto commented this would roughly be a 5.0L engine, internet commenters inevitably brought up “why not swap in a 5.0L Coyote engine or LS Swap a Honda” entirely missing out on the proof of concept and purpose of this engineering project.

“I have gotten a lot of questions about this being a Coyote engine…the ironic thing…I have one in my garage (technically a Voodoo) in my Shelby GT 350. So ya, I hear you, but this is going to sound and be totally different.”

“The blue outline is a Coyote V8 compared to my engine for size reference. The exhaust and intake are still in design.”

Regarding the opposing heads,

On most V or horizontally opposed engines, you have two different cylinder heads. One head is a mirror image of the other. By facing one head to the rear of the engine you can use a single cylinder head design. This cuts down on cost by a ton and makes the project more doable.”

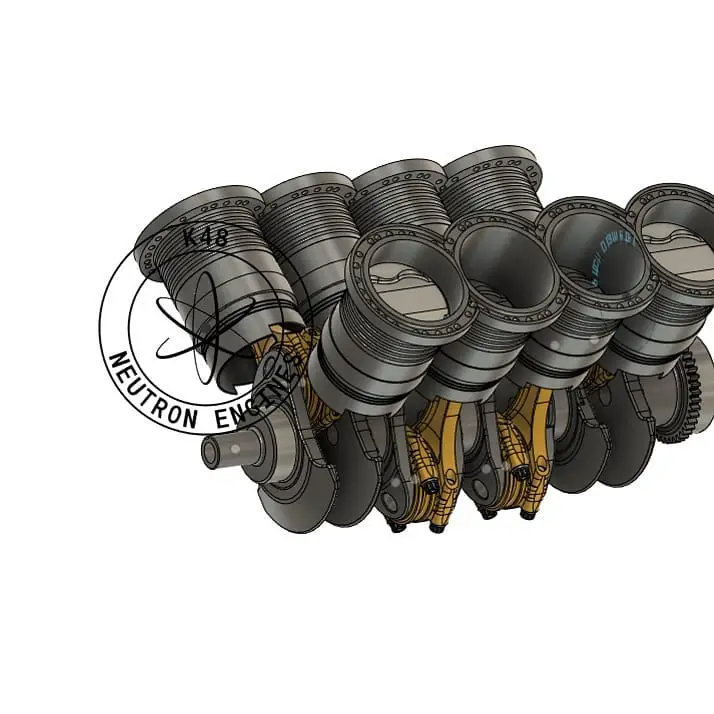

“Here is the rotating assembly for my custom honda k series V8 and the Darton mid sleeves. I hope you can see the flat-plane crank and imagine what this will sound like at over 9k rpm.“

The gear at the rear of the crankshaft drives the rear-facing heads timing chain. This gear allows for a stock style k20 head to be bolted up to the engine. Usually, a V8 engine or a horizontally opposed engine would have two different cylinder heads, with one cylinder head a mirrored copy of the other. This design saves money and makes this engine realistic.

As for details, according to Williams,

“I am hoping for close to 10,000 RPM or more. Custom titanium rods, and custom pins help achieve those numbers. I also need a crazy good head that can flow and get to that point. That is where Prayoonto racing comes in.”

In its stock, unmodified form, the most powerful K24 found in the Acura TLX puts out a healthy 206 HP and 182 lb-ft.

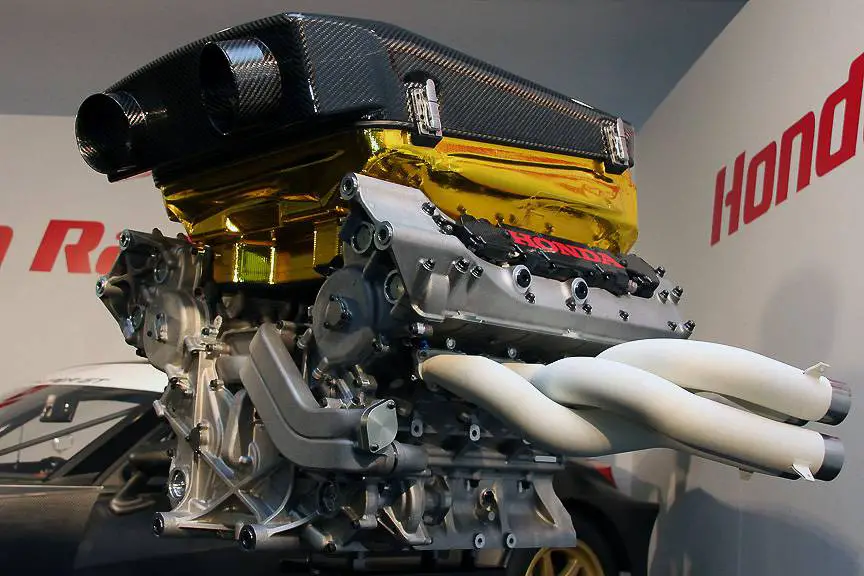

Honda’s Super GT and Indycar engines make a conservative 550 plus HP, dependable enough for a full race season.

With enough money, experience, and the right parts, drag racers who want to stay naturally aspirated easily bring these K-series engines up to 600 HP and beyond (as mentioned, no turbos needed.)

How much this engine makes with those drag racing heads and cams, your guess is as good as mine. With that much displacement revving at 10,000 RPMs, north of 600 HP is well within reason.

This is a project I expect to take several months, at the very least, so subscribe to his Instagram above for updates.

[…] Source: Tire Meets Road […]